Designed for aseptic applications and to comply with the most stringent cleanability and sterilization requirements.

Designed for applications in which CIP/SIP compliance is crucial. Using tank bottom valves in aseptic processing ensures the system can be easily sterilized and cleaned in place (CIP/SIP).

Designed for clean steam and condensate applications using FDA and USO VI compliant elastomers. ASME BPE, DIN and ISO pipe diameters, and a full range of automation and controls are available.

Designed for compliance with validated cleaning procedures in sterile and aseptic process lines requiring highly efficient cleaning devices. Axial and radial cleaning devices with ATEX are available.

Designed for aseptic applications requiring high-level cleanability involving sterilization processes. Full traceability certification is available, examples include DIN32676, DIN11851, DIN11853, DIN11864, ASME BPE, 3A, and ISO.

Designed for fluid transfer with cleanroom manufactured silicone, PFA, and PTFE to be compliant with bio-pharmaceutical standards and are FDA certified and USP Class VI. Optimal performance is achieved at various temperatures and pressure conditions and in ATEX areas in accordance with ISO 14644-1 Class 8.

•Aseptic

•Diaphragm is FDA, FDA, and USP VI compliant

•ASME and SMS 316L stainless

•Manual or pneumatic actuated NO/NC

•Mixproof valves

•316L stainless, other alloys available

•Optional bellows in FDA and USP VI compliant materials

•Body with controlled sulphur

316L / 1.4435

•Forged or investment cast

•Manual or pneumatic actuated

•2-way block valves from wrought material

• EPDM, PTFE membranes are USP VI compliant; Buna-N white butyl membranes are FDA and USDA compliant.

•Sizes: DN8 –DN100

•Sizes: 3/8" - 4" DN10 - DN100

•Solid body 1.4404, 1.4435

•EPDM gasket and PTFE bellow are

FDA and USP VI compliant

•Connection: buttweld acc 11866 1-3

•Pneumatic actuated NO/NC

•Sizes: 1/2" -3"

•Solid body 1.4435

•Silicone, EPDM, and PTFE diaphragms are FDA and USP VI compliant

•Connections: tri-clamp and butt weld acc ASTM A269/270

•Manual or pneumatic actuated NO/NC

•Sizes: 1/2" - 4"

•Solid body 1.4435 / 316L stainless

•EPDM, PTFE, and TFM membranes are FDA and USP VI compliant

•Connections: tri-clamp or buttweld acc 11866 1-3

•Manual and pneumatic actuated NO/NC

•Sizes: 1⁄2" - 3" DN10 - DN80

•Solid body 316L stainless

•Silicone, TFM diaphragms, other materials available on request

•FDA and USP VI compliant

•Weld pad with hygienic clamp

•Connections: tri-clamp or buttweld acc 11866 1-3

•Manual or pneumatic actuated NO/NC

•Direct acting, spring loaded •Compact design machined from 316L bar stock

•Internal SF1, External SF3

•EPDM, Viton™, and PTFE diaphragms are FDA and USPVI, ASME, DIN, ISO TC,DN32-DN50, and assembly in cleanroom ISO Class 8 compliant

•Classic, mini, combination, and compact systems available

•For use in sterile and CIP / SIP applications

•Compact design for easy integration

•Weld ends are standard, other connections are available

•Includes: 50ml - 1000ml bags, bottles, syringe, 1-9 probes

•Single use system also available

•Simple, easy to maintain hygienic design

•316L is standard, other alloys available

•All materials are DA compliant

•Sizes: 1⁄2"-2"

•316L machined bar stock

•Self-draining

•SF1 internal finish

•Connections: ASME, DIN, ISO tri-clamp, or buttweld

•Vertical or horizontal installation

•Low subcooling operation

•316L body, Viton™ seals

•Self-draining

•SF1 internal finish

•Connections: DN15-DN80, ASME , DIN, or ISO tri-clamp

•Assembly in cleanroom ISO Class 8 compliant

•3-piece true bore floating ball design

•316L casting, ferrite <2% , other alloys available

•Anti blow-out stem, ISO 5211 mounting

•PTFE seats, TFM cavity filler optional

•Connections: DN10-DN100, ASME, DIN, ISO tri-clamp, or buttweld tube with ETO internal SF5

•Assembly in cleanroom ISO Class 8 compliant

•2-way valve with purge holes

•Permits sampling of steam for purity and safely isolates trap for easy maintenance

•316L, other materials available •Connections: DN15-DN40, ASME, ISO DIN, tri-clamp, or weld ends ETO

•Used for general blending applications from 50-30000L

•Aseptic

•No mechanical seals

•Suitable for CIP/SIP

•ATEX

•General blending or homogenizing applications from 50-10000L

•Used for suspending, downsizing, emulsifying, and CIP/SIP

•ATEX

•Used for suspending, downsizing, emulsifying, and CIP/SIP

•External stand alone

•Connection: tri-clamp

•ATEX

•Compact axial rotating cleaning head

•Gas tight, aseptic design

•External actuation, contactless magnetic transmission

•316L body, PTFE bushings are CIP validated and FDA compliant

•Maximum working temperature 110°C

•2-4 nozzles with 2-4mm orifice

•ATEX

•Compact axial rotating cleaning head

•Gas tight, aseptic design

•CIP validated

•PTFE bearings, 316L body, other alloys available

•Machined bar stock

•Working pressure: 1-15bar

•Media driven

•ATEX

•Compact axial rotating cleaning head •Gas tight, aseptic design

•CIP validated

•PTFE bearings, 316L other alloys available

•Machined bar stock

•Working pressure: 1- 15bar

•Media driven

•ATEX

•Compact axial and radial high- pressure cleaning head

•CIP validated and FDA compliant

•1.4571 (316Ti)

•Working pressure: <50-250bar

•Temperature: up to 180°C

•External motor driven

•2-4 nozzles, 1- 3mm nozzle orifice •ATEX

•Sanitary tri-clamp gasket material: Silicone, EPDM, PTFE, Viton™, Gylon®

•Acc. ISO; DIN, ASME, FDA and USP VI. AD available on request

•Bypass for local maintenance, pump service, instrument or flow meter calibration

•316L body with tri-clamp or customized

•EPDM diaphragm is FDA and USP VI compliant

•Suitable for all leading diaphragm valves manufacturers

•Easy installation using the same threads as actuator manufacturer TopWorx™

•All plates are polished

•Bolts and nuts have FDA approved lubrication

•304 and 316L

•Sizes: 1/2"-4"

•Hang plate, weld plate, and base mount

•Temperature range:-40-160°C

•Insert material: FDA approved silicone, blue colour, 80 durometer, Santoprene™ available on request

•Silicone coating

•For use with ultra pure media and clean steam

•Manufactured in cleanroom ISO 14664-1 Class 8 standards, compliant with FDA and USPVI

•Lot and batch number

•Sizes: 3⁄4"-2"

•Connections: tri-clamp, buttweld, and reusable aseptic

•FDA hose with stainless steel braid

•Connections: a variety available

•Provides excellent chemical resistance

•Conductive options available

•Platinum cured silicone STHT-R and STHT-W for use with ultra pure media

•Manufactured in cleanroom ISO 14664- 1 Class 8 standards, compliant with FDA and USPVI

•Lot and batch number

•Sizes: 1⁄4"- 4"

•Connections: tri-clamp, buttweld, and reusable aseptic

•Reusable, aseptic

•Connections: tri clamp or buttweld

•Bushing made of autoclavable PVDF, 1.4435 BN 2 Fittings

• Internal SF 1

•Easy installation, no tools lubricants

•Pressure level is always given by used hoses

•Sizes: DN06-DN80 acc ISO, DIN

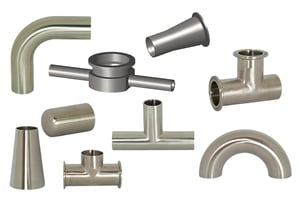

•ASME marking with dimension and pipe standard, material number, casting number, and manufacturer code