A range of metallic, rubber, PVC, and composite industrial hose assemblies certified to the Pressure Equipment Directive 2014/68/EU are available for a variety of applications.

Product range includes rotary and linear control valves, pressure reducing and back pressure regulators, and vapor control systems (VCI) according PED, ATEX, CE. Available models withstand the high temperatures and pressures found in cryogenic and corrosive fluid applications and aid in maximizing the reduction of fugitive emission.

Provides innovative pressure control solutions for light industrial and utility applications according to PED, ATEX, CE, CRN. Available models withstand the high temperatures and pressures found in cryogenic and corrosive fluid applications and aid in maximizing the reduction of fugitive emission.

Vapor control systems and flame arresters provide a wide range of safe pressure relief and vacuum service.

Inline and end of line safety devices are manufactured according ATEX 114 and DIN 16852.

Complete range of steam traps manufactured in multiple materials and sizes (DN15 to DN150), designed for pressures up to 80bar and flow rates of over 100,000 Kgs/h.

The coupling range includes many options to complement our hose offering whether used to make hose assemblies in-house or for plants, tankers, or machinery. Products include standard crimped couplings, cam and groove, and genuine Boss™ steam fittings.

•PED compliant, flexible

•Suited to high pressure, high temperature and corrosive applications

•Meeting EN10380 standards

•Available in ANSI 304, 316, 316L, and 321 stainless steel

•Suitable for transferring chemicals, foods, pharmaceuticals, oils, gas, fuels, and steam

•Extruded and mandrel-wrapped

•Designed for air, water, multi-purpose, chemical, steam, oil, LPG, food and beverage, and bulk handling applications

•Certified to relevant standards

•Flexible, weatherproof, and abrasive-resistant

•Designed for oil, chemical, cryogenic, and LPG applications

•Assemblies are electrically resistant to <10 ohms to BS5842:1980 clause 6.2 (EN ISO 8031)

•Designed to transfer a variety of media including: water, slurries, abrasive media, oils, and media in non-food, or food sectors

•Certified to relevant standards

•Hand-built rubber hose assemblies with built-in or crimped ends

•Designed for applications marine, offshore, dockside, dredging, and heavy industry applications

•Built to bespoke customer's requirements, and according to application

•Designed and engineered to bespoke requirements including heat shrink and jacketed covers

•Metallic and industrial hoses are available with electric heat trace cabling to facilitate heating of the hose body ensuring continuous flow of product

•GSM ball joint armoured

•Available in galvanised steel and

stainless steel

•Suitable for low- and high-pressure conditions including harsh high-pressure hydraulic applications

•Self contained

•Flow to open design with extended guiding

• Intended for process fluids and cryogenic applications

•Sizes: 1/2"-2"

•End connections: NPT, flange

•High capacity back-pressure regulator

•Dome loaded with optional pilot and air sets

•Intended for process fluids and cryogenic applications

•Sizes: 1/2"-4"

•End connections: NPT, flange

•Pressure loaded

•Flow to open design

•Intended primarily for clean natural gas and fuel gas applications

•Sizes: 1"-4"

•End connections: NPT, flange

•High performance, self-relieving

•Flow to open design

•Internal pressure balancing piston cylinder

•Sizes: 1/2"-4"

•End connections: NPT, flange

•Pneumatic / Rotork electric actuators

•Compact design

•Available in stainless steel or bronze glove styles, cryogenic options available

•Sizes: 1/2"-2"

•End connections: NPT, flange

•Heavy duty control valve provides maximum protection against leakage

•Metallic bellows stem seal with live-loaded secondary stem packing seal

•Sizes: 3/4"-2"

•End connection: flange

•Universal rotary style

•Versatile, adaptable, and easily maintained

•Quick trim service and dual seating design, Class VI

•Sizes: 1"-8"

•End connection: flange

•Globe style

•Unibody is a forged ISO-statically compact virgin TFE block encased

with a 304 stainless steel body cover

•Dual stem seal, quick change trim

•Sizes: 1/2"- 2"

•End connection: flange

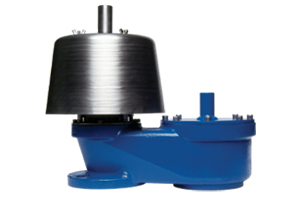

•Weight loaded pressure / vacuum vents, optional spring loaded

•Onsite retrofit is optional

•Sizes: 2"-12"

•End connection: flange

•Low pressure pilot operated

pressure / vacuum vent

•Precision of pilot allows tight seat, leakage closer to set

•Point and full flow available

•Sizes: 2"- 12"

•End connection: flange

•Low pressure, spring operated tank blanketing style, pilot operated optional

•Sizes: 1", 2"

•End connections: FNPT, flange

•Tank manifold, venting and blanketing over 1 nozzle styles

•Sizes:

-Tank nozzle: 2"-12"

-Blanketing connection: 1⁄2"-2"

-Venting connections: 2"-12"

-End connection: flange

•Inline detonation flame arrester

•Bi-directional horizontal or vertical installation

•Sizes: DN20 –DN300

•End connections: RP, BSP, NPTF, DIN, ASME

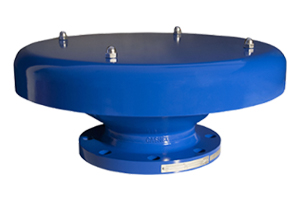

•End of line deflagration flame arrester

•Sizes: DN400 –DN600

•End connections: flange ASME 150, API 650, DIN PN 16

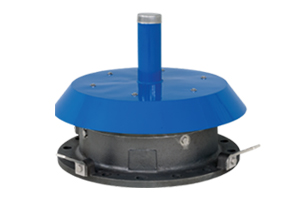

•Emergency pressure / vacuum vents

•Provides relief of excessive internal pressure

•Sizes: DN20-DN300

•End connections: standard DIN Flange EN 1092-1 PN 10.ASME B 16.5

•Linear actuator

•Single seated direct or reverse acting styles

•Metal-to-Metal sealing standard

•For use in water, super-heated water, steam, air and gas, PN16-PN40, DN15-DN100 applications

•Pilot operated pressure reducing valve

•Soft faced valve plug

•For use in saturated steam, compressed air and gas, PN16-PN40, DN65-DN100 applications

•Direct acting pressure reducing valve

•Compact design

•Bellows designed provides high durability

•Built in strainer

•For use in steam, compressed air, gas and water applications

•Air vent integrated

•Steam tap series provides modulating and air discharge

•Sizes: 1⁄2"-2"

•End connections: RP, DIN flange, ANSI flange

•Simple, robust steam traps and air vents

•Sizes: 1⁄2"-1"

•End connections: RP, DIN flange PN40, ANSI flange

•For steam processes where condensate sensible heat can be recovered to reduce steam consumption; excellent for use with super-heated and saturated steam

•All Dixon, Boss-Lock and EZ Boss-Lock cam and groove couplers and adapters are produced to interchange with all product produced to MIL-C-27487, A-A-59326B Specification

•A comprehensive range of hydraulic and pneumatic quick connect / disconnect fittings for plant maintenance and fluid handling applications

•Wide selection of materials and sizes available with interchanges to all major manufacturers

•Genuine Boss steam fittings include steam adapters, steam clamps, stems, and ground joints

•Tankwagon couplings (TW couplings, tanker couplings, EUROcouplings) are commonly used for loading / unloading of tankers and in chemical, petrochemical or food industry applications

•Manufactured according to EN ISO 14420-6 standard (former DIN 28450)

•Used in fire protection systems and for transportation of liquid and dry bulk material found in chemical, food, agriculture, construction, irrigation, sewage transport, and road tanker applications

•Available in a range of sizes and materials

•Split, swivel, TTMA, ASA, PN16 and ANSI options available

•Used wherever a leak-proof swivel connection is needed in pipelines or in combination with hose assemblies to eliminate hose twisting

•Various configurations available

•Full range of dry break and dry disconnect couplings available

•Sizes: 3/4" - 8"

•Variety of body and seal materials available

•Designed for the quick and spill-free connection and disconnection of hoses and pipelines